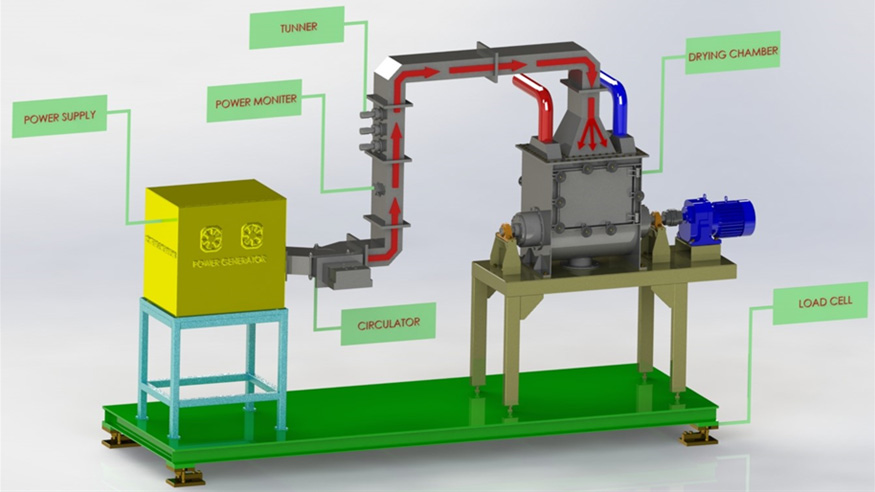

Smart Microwave Compound Dryer

Smart Microwave Compound Dryer

The Smart Microwave Compound Dryer operates with enormously higher efficiency compared to general dryer. Its field of application is very wide and has the following characteristics.

- 1)Problems of the conventional microwave drying machine in Korea

- Currently, most of the mw drying machines used in Korea are equipped with small magnetron below the power of 1kw ~ 3kw.

- When one small magnetron is installed, the users can get the desired results. However, when several magnets are installed, both efficiency and stability become poorer.

- 2)Effective side-by-side comparison with traditional small microwave dryers

- materials : Potassium Hydroxide (5kg )+ Water(2kg)

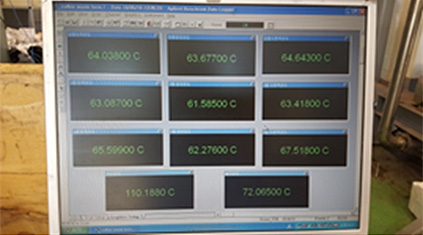

| 1kw,2set(total:2kw) | |||

|---|---|---|---|

| Time(min) | Humidity(%) | Temp('C) | 7% under |

| 0 | 29.91 | 19 | |

| 30 | 27.23 | 57.1 | |

| 60 | 21.94 | 68.5 | |

| 90 | 14.97 | 75.6 | |

| 120 | 12.03 | 76.5 | |

| 20kw(10%,used 2kw) | |||

|---|---|---|---|

| Time(min) | Humidity(%) | Temp('C) | 7% under |

| 0 | 27.93 | 19 | |

| 10 | 18.32 | 95.8 | |

| 20 | 9.81 | 98.7 | |

| 30 | 5.25 | 103 | |

Test Result : more than 4 times difference in drying time

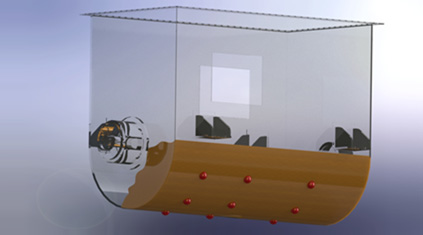

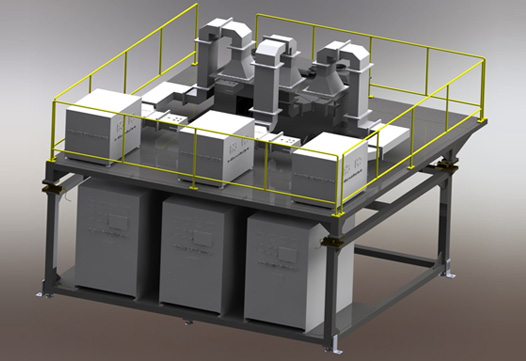

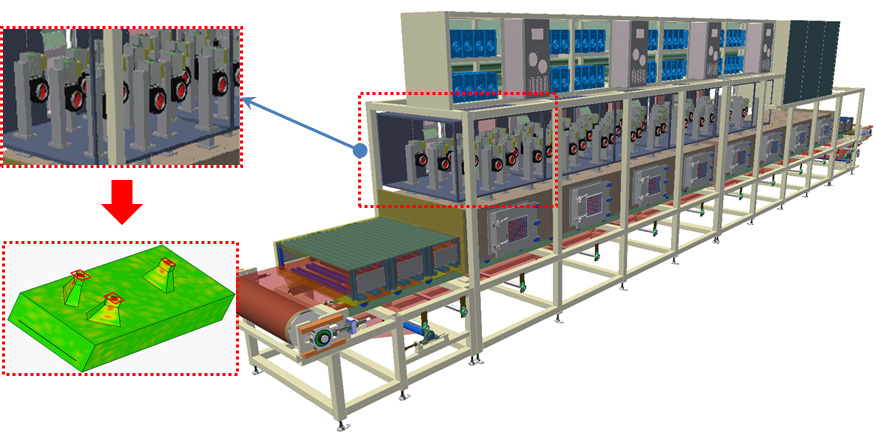

Design example with several small capacity

Design example with several small capacity- * Used multiple small capacities - Efficiency due to frequency interference

* Used Big size capacities - High efficiency ,stabilize, optimization

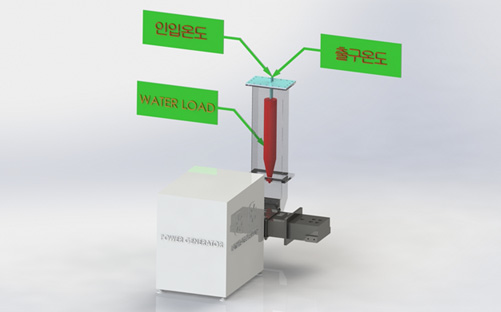

- 3)Multiple Small Microwave Dryer and Economical Comparison

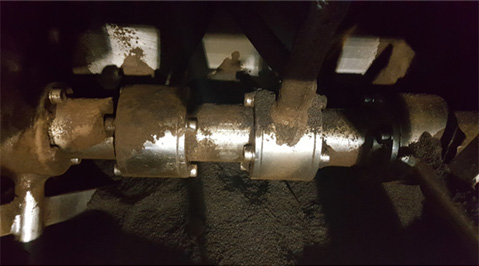

- The following figure is the basic structure of microwave

Insulation Drying Comparion

| 2kw x 10set(mw)(Utility mounting) | 20kw, 1set (Utility mounting) | |

|---|---|---|

| PRICE | $5,200x10set = $52,000(exclusion of control) | $63,700(exclusion of control) |

| efficiency | 45~50% | 75%(Certification Experiment) |

| 10set operation(1year electric price) | $198,845 | $105,380 |

| Reduced operating costs, 1.5 years for initial investment recovery | ||

Health salt Drying

| Air Heating flow | MW Drying | |

|---|---|---|

| INPUT | 400 kg | 300 kg |

| drying time | 8hour | 60min |

| energy consumption (kW) | Heater50 + Motor11 + Fan7.5 = 78.5 | MW60 + Motor7.5 + Fan5.5 + Heatpump3 = 66 |

| Day electric consumption | 78.5kW×8h=628kW/day | 66kW×8h=528kW/day |

| Day electric price | 628kW×0.2$=125.6$ | 528kW×0.2$=105.6$ |

| 2.4ton Production electric price | 125.6$×6set×300day= $226,080 | 105.6$×300day=$31,680 |

| day capacity | 400 kg | 2400(8batch) kg |

| Electricity used per kg | $0.314 | $0.044 |

1 kW unit it is difficult to fit everything in terms of cost, which is related to the lifetime of the equipment.