Structure and Mixing Principle of Continuous Mixer

- • Shape that makes the most advantage out of batch-type non-gravity mixer.

- • Form with attached non-gravity mixer.

- • Mixing and conveying of raw materials are performed simultaneously by rotation of paddles.

- • Inputs and discharges of raw materials are simultaneously processed, enhancing production per unit time.

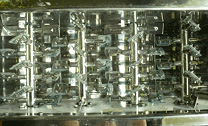

Paddle Mechanism

Paddle Mechanism Paddle Layout

Paddle Layout

Characteristics of Continuous Mixer

- • It is easy to mix raw materials even with large difference in particle size andproportion.

- • It is possible to mix fragile raw materials.

- • Takes up less space than other continuous mixers.

- • Easy to continuously produce single type of product.

- • Facility is simplified, no need for complex facilities.

- • Advantageous not only for mass production but also for small production sites.

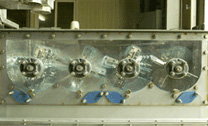

Continuous zero gravity mixer 1 (pilot)

Continuous zero gravity mixer 1 (pilot) Continuous zero gravity mixer 2 (pilot)

Continuous zero gravity mixer 2 (pilot) Continuous zero gravity mixer 3 (pilot)

Continuous zero gravity mixer 3 (pilot) Continuous zero gravity mixer

Continuous zero gravity mixer

Application field

| Field | Contents |

|---|---|

| Food industry | Coffee, frozen vegetables, seasoning, ramen seasoning, cereal, sugar, salt, etc. |

| Chemical industry | Carbon products, detergents, fragrance, PC, etc. |

| Ceramic | Refractory, flame retardant, clay / sand |

| Dry Mortar | Cement, building materials, fly ash |

| Pharmaceutical Industry | Animal medicine, pesticide |

| Other fields | Liquid coating field |